Hyundai Mobis, a South Korean auto parts developer under Hyundai Motor Group, said Wednesday that it has developed a sound-based artificial intelligence system that can determine the accuracy of product quality from sounds generated during inspection. It has applied the AI technology at its manufacturing site.

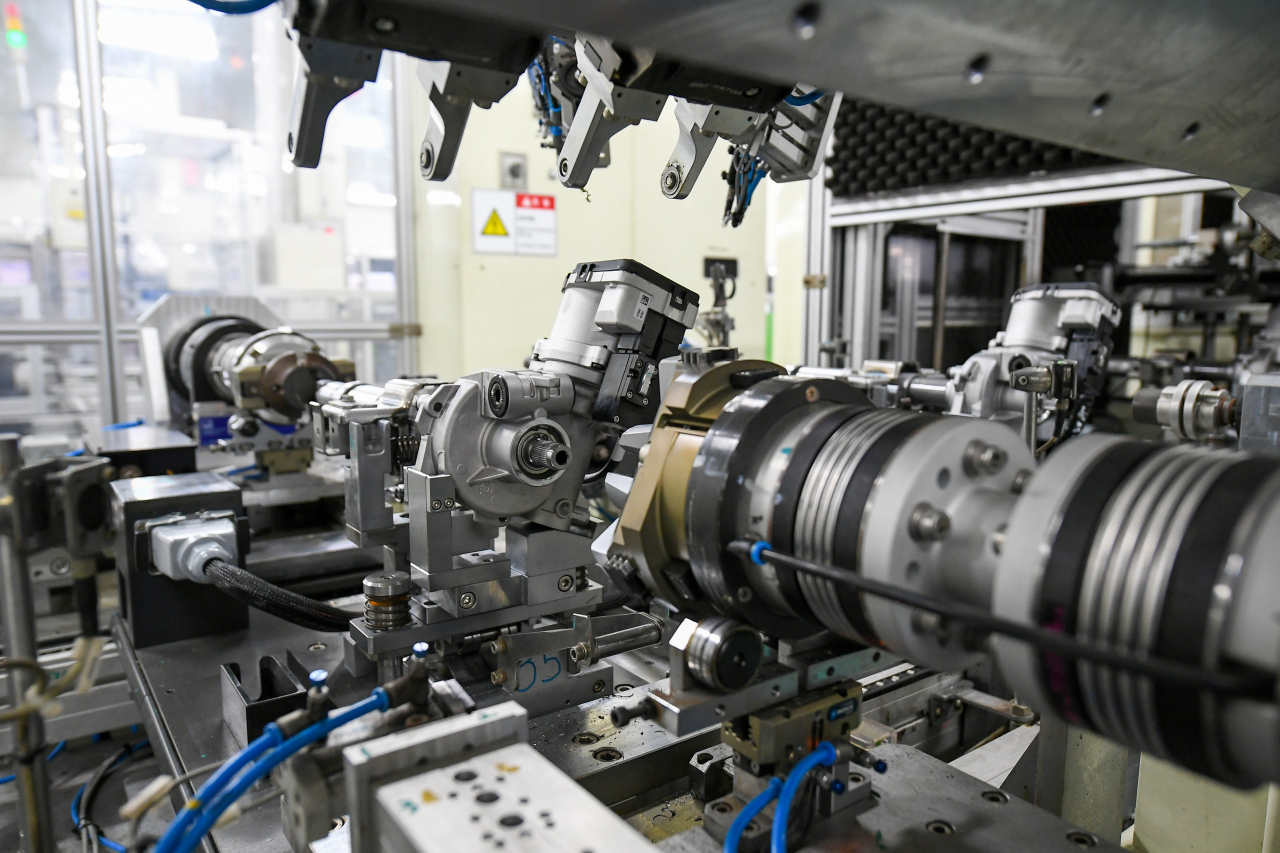

According to Hyundai Mobis, a new technology called Acoustic AI has been installed at its Changwon plant in South Gyeongsang Province, which rolls out motor-driven power steering products.

The company explained that Acoustic AI is based on an algorithm that can give meanings to certain sounds and make judgments accordingly, noting that the sound-based AI tool is different from recent generative AI technologies based on language.

Hyundai Mobis pointed out that Acoustic AI only takes one second to check the quality of each product. To assess the quality of each motor-driven power steering, or MDPS, unit, the AI system reviews the sound waves created from the spinning of the motor attached to the MDPS to determine whether there are any irregularities.

Prior to Acoustic AI's development, the products that were suspected of not meeting standards were screened by an automated system and experts had to reassess them again. The company said the new AI system improves the accuracy and pace of the quality check process.

Starting with its Changwon plant, Hyundai Mobis plans to expand Acoustic AI's usage to other auto parts manufacturing lines, including brake equipment, that naturally cause noise during the production process. In doing so, the company aims to keep securing more data for the already developed sound-based AI system and advance its accuracy.

“This initiative marks a pioneering example of process innovation not only in the automotive sector but also across the global manufacturing industry,” said Choi Nak-hyun, vice president and head of digital transformation at Hyundai Mobis.

“We will continue to introduce differentiated, new AI-based technologies for production, research and development and improvements in the work environment.”

-

Articles by Kan Hyeong-woo

![[Business Diplomacy] As Trump targets EVs, Hyundai-Kia shifts gears to hybrids](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=644&simg=/content/image/2024/07/30/20240730050592_0.jpg&u=20240730155845)

![[KH Explains] Hanwha scion steps into spotlight amid pending succession](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=644&simg=/content/image/2024/07/30/20240730050625_0.jpg&u=20240731124143)